Understanding CNC Plasma Cutting

Once upon a time, metal fabricators had to cut pieces by hand, using heavy-duty saws and shears. Fortunately, those methods have long since been replaced by the use of high-powered cutting torches and machine-mounted saws. Yet even these techniques require skilled operators and can be quite time-consuming.

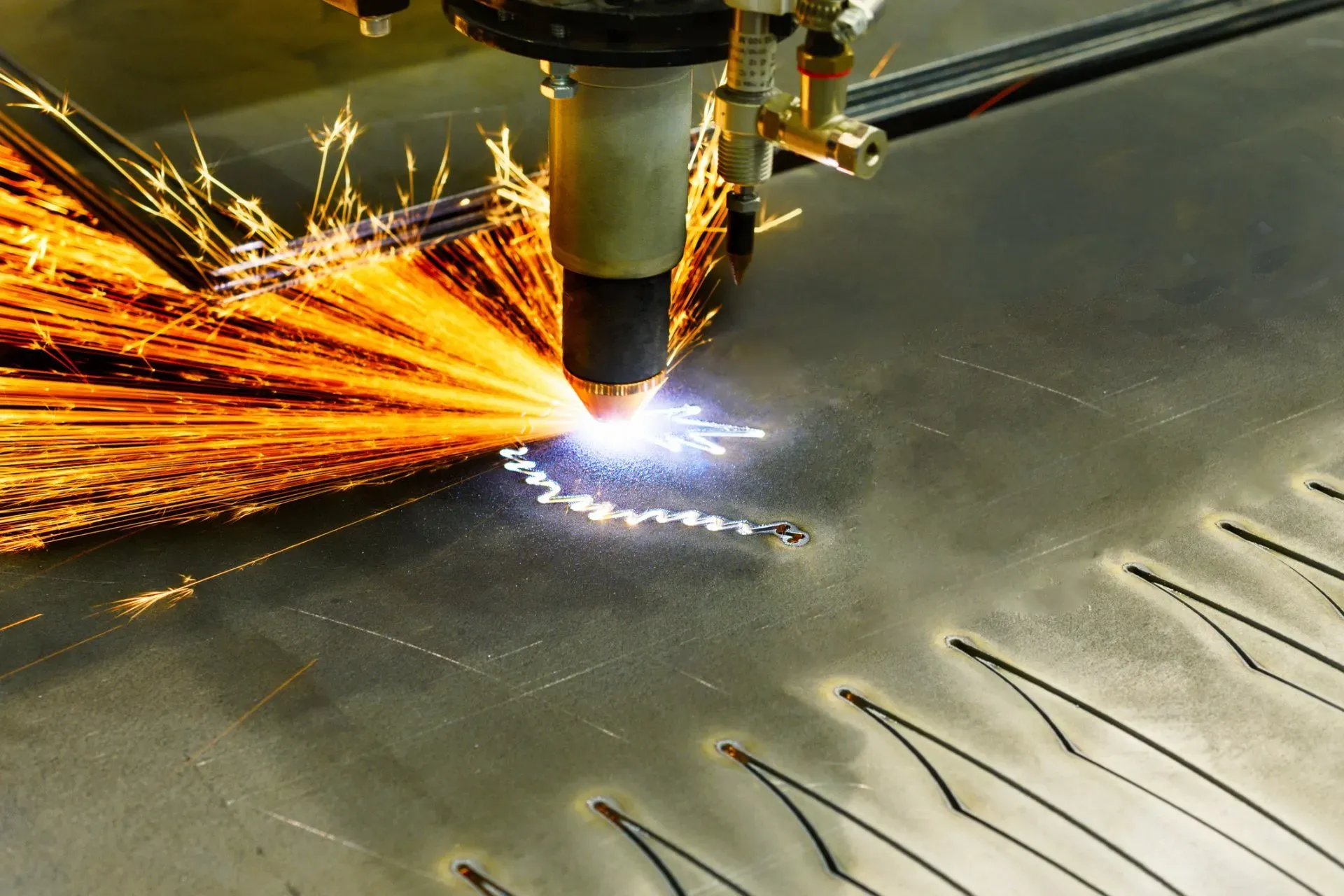

More recently, many metal workers have begun to utilize a technique known as CNC plasma cutting. This method offers huge benefits in terms of speed, accuracy, and repeatability. Yet many people outside the metalworking industry fail to appreciate the advantages of CNC plasma cutting. This article will present a useful overview of this cutting technique.

CNC

CNC plasma cutting derives its benefits through the conjunction of two different techniques: CNC machining and plasma cutting. CNC — short for computer numerical control — has quickly gained a foothold in countless industries from manufacturing to fabrication to heavy industry. CNC machining uses sophisticated new computer technology to manipulate tools previously operated by hand.

CNC technology has two components. First, there are the tools themselves — in this case, a plasma cutter. The plasma cutter is controlled by a computer, which is the second component. This method of control allows the tool to make cuts with an incredible degree of accuracy that would be difficult for a human operator to achieve.

The cutting tool receives its instructions from a computer equipped with sophisticated modeling software. Such software allows designers to create highly specific templates of the part to be machined. Signals then relay this information to the plasma cutter, which carries out the work.

As noted above, CNC technology allows for unprecedented accuracy. Part after part can be created to precisely the same specifications. Not only that, but the cutting usually takes much less time. As a result, CNC machining helps to lower overall shop costs while promoting greater efficiency by increasing the amount of work that can be accomplished in a given period of time.

Plasma Cutting

Many CNC machines involve the use of traditional saw blades, drill bits, and other mechanical tools. Plasma cutting takes a much different approach. Cutting is accomplished by means of a highly focused stream of electricity, which melts the metal. This electricity travels to the metal through a stream of ionized gas, otherwise known as plasma.

The machine directs the plasma at the metal through an orifice with a very small diameter. In addition to relaying the electrical current that melts the metal, the plasma also removes any molten metal from the work area. It accomplishes this thanks to its high velocity, literally blowing the molten metal away and thus allowing the cut to be completed.

Many people confuse plasma cutting with another gas-powered type of cutting known as oxy-fuel cutting. Yet a crucial difference exists between the two in terms of the way in which the cutting happens. Oxy-fuel oxidizes the base metal. In other words, it literally burns through the metal.

While effective when dealing with steel, oxy-fuel does not work for cutting through non-ferrous metals like aluminum and stainless steel. The nature of these metals makes them impervious to oxidation. Yet plasma cutting, which melts through the metal using an electrical impulse, can effectively cut through any material capable of conducting an electrical impulse.

Plasma cutting offers a further benefit in terms of cutting speed, which tends to be much greater than that of oxy-fuel, especially when used in a CNC set-up.

A CNC plasma cutting set-up opens up whole new worlds of efficiency and precision when it comes to metal fabrication. To learn more about what CNC plasma cutting can do for you, speak with the metal services team at Schorr Metals Inc.