Everything You Need to Know About Galvanized Metal

Selecting metal for the product you are manufacturing or the building you are constructing is one of the biggest decisions you need to make. The type of metal you select can affect the lifespan, durability, and type of maintenance that your product or building can require. It can also affect your budget and costs associated with your project.

Learning about the various types of metal that are on the market can help you determine which metal is ideal for your metal product or building. Read on to learn more about galvanized metal and everything you need to know if you are considering using this type of metal.

What Is Galvanized Metal?

Galvanized metal is metal that undergoes the galvanization process. The galvanization process is the process of applying a thin coating of zinc to different types of metals. Different methods are used to galvanize metal, including hot dipping, pre-galvanizing, and electrogalvanizing.

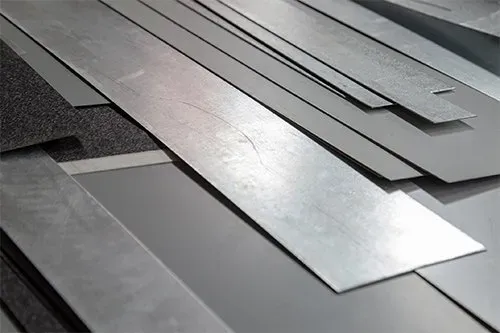

You can tell that metal is galvanized when it has a pattern to it that is known as a spangle pattern. A spangle pattern almost looks like someone dipped a sponge in gray paint and then sponge-painted the metal. You’ll notice darker and lighter spots, much like you would see when a wall is sponge painted.

What Types of Metal Can Be Galvanized?

Iron and steel are the two most common types of metals that are galvanized. However, they are not the only types of metal that can receive this treatment.

Most ferrous metals are able to be galvanized, while most non-ferrous metals are not able to be galvanized. If you are unsure if a metal is ferrous or non-ferrous, a magnet can help enlighten you. If a magnet sticks, you have a ferrous metal. If the magnet doesn't stick, you are dealing with a non-ferrous metal.

What Are the Advantages of Galvanized Metal?

Galvanization is primarily performed to prevent your main metal material from rusting or corroding. When a layer of zinc is added to a sheet of metal, the zinc itself will rust or corrode. While this may sound like a negative, it is actually a positive.

Since the zinc is rusting or corroding, it is preventing or slowing the more expensive and vital metal from rusting or corroding. This helps to protect your more important metal source from the damaging effects associated with rust and corrosion.

Helping to slow or protect against rust and corrosion can help extend the lifespan of your metal and reduce the amount of maintenance the metal may need.

The other major benefit associated with galvanized metal is that the zinc coating is long-lasting. You can purchase many products and sealers to protect your metal against rust and corrosion. Many of these coatings wear off in a matter of years due to weather exposure. Zinc can last upwards of 50 years, which prevents you from having to coat your metal again in the future.

Are There Any Drawbacks to Galvanized Metal?

One of the biggest drawbacks to galvanized metal is that the galvanization process helps to hide imperfections, flaws, and problems with the metal. As such, you may miss problems with metal that require immediate repair or maintenance.

Another drawback to galvanized metal is that the coating is not always smooth. When it is used inside of pipes, it can lead to items getting stuck on the rough surface, which leads to blockages and obstructions within the pipe.

If you are looking to purchase galvanized metal, such as galvanized steel, or you want galvanized metal formed or cut for your project, Schorr Metals Inc. can help you. Give Schorr Metals Inc., located in Placentia, CA, a call today to inquire about purchasing metal or our metal services.